Family-Owned Food Manufacturer | Supply Chain

New transportation strategies satisfy consumer demand—while cutting costs by 10%

What We Did

With consumers increasingly demanding fresher products and more frequent deliveries, a national food manufacturer knew they needed to transform the company’s supply chain and transportation function.

Executives looked to West Monroe to:

- Overhaul and align the company’s supply chain and transportation strategies

- Implement new technology to increase visibility, improve data validity, and strengthen relationships along their supply chain

- All while maintaining (or improving) first-rate customer experience

$3M

20%

5%

Project Timeline

The Challenge

Consumers are looking for fresher, shorter shelf-life products, and more frequent deliveries. This means the family-run national food manufacturer needed to overhaul its supply chain. They partnered with West Monroe do just that—with new processes, technologies and operational management strategies.

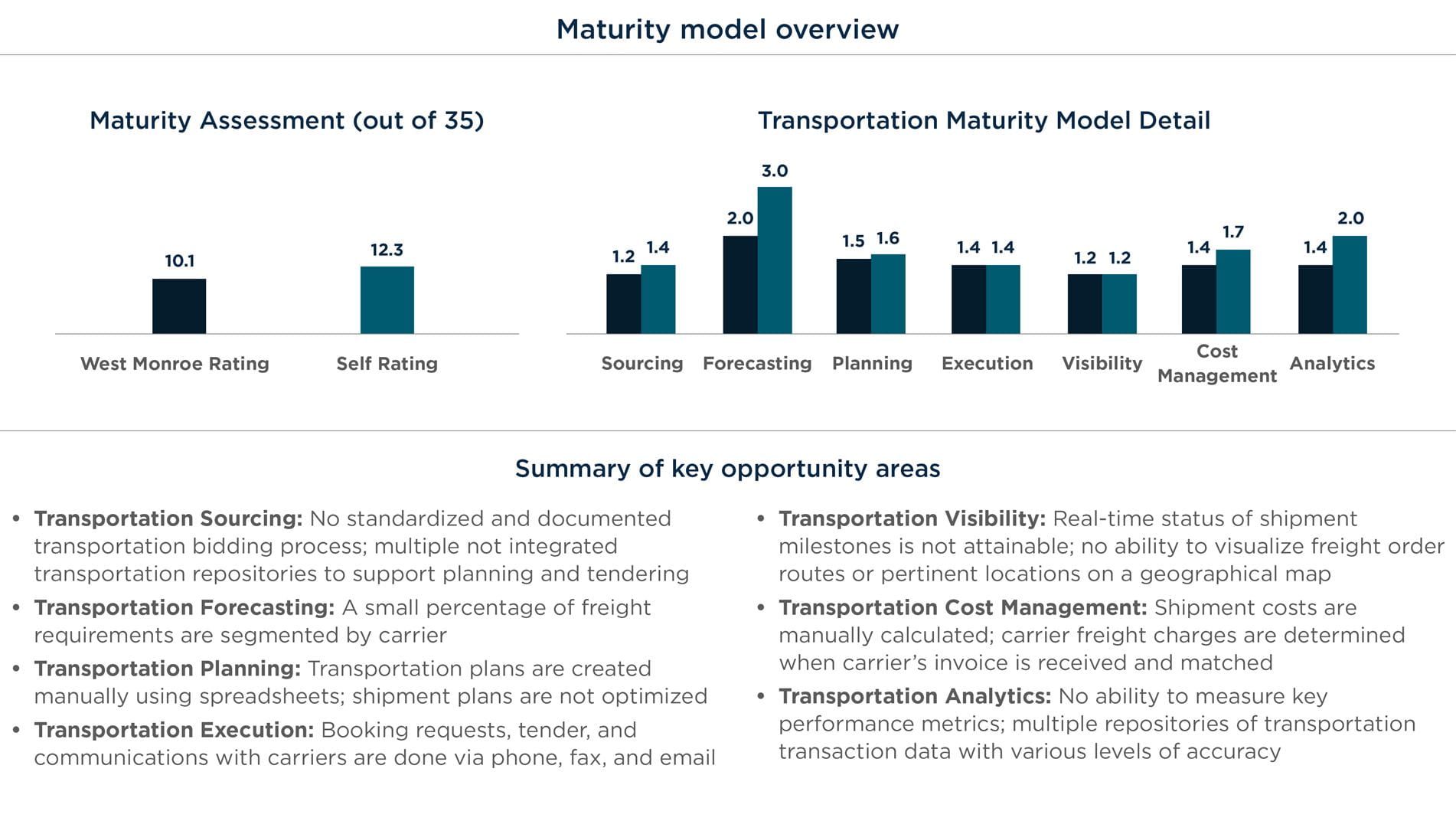

In an initial assessment, West Monroe’s multidisciplinary team of supply chain management, process optimization, technology, and change management experts identified several objectives for this project:

- Maintain or improve customer service and experience

- Reduce risk in the supply chain

- Lower overall transportation cost

- Increase capacity for growth

Our team was also tasked with improving data validity and supply chain tracking capabilities, as well as strengthening relationships across the supply chain.

An Undeniable Approach

After our team’s initial analysis, we knew managing change would be the toughest roadblock for the manufacturer—but West Monroe built a strong foundation to support the transformation.

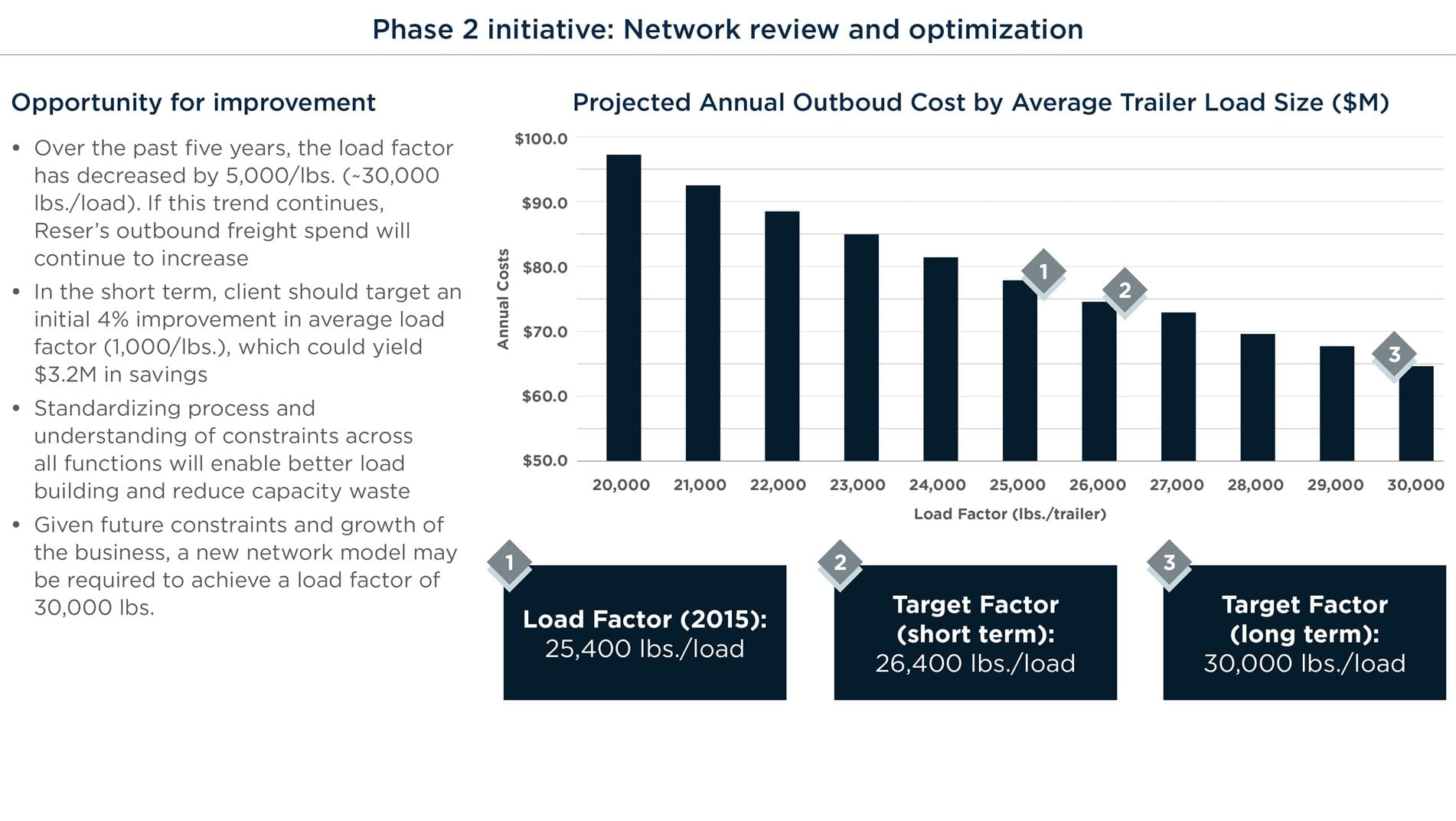

Together with the manufacturer’s leadership team and transportation department, we developed a strategy that encouraged relationships with asset-based carriers, matched rates to industry benchmarks and reduced the size of the company’s carrier portfolio to improve service, capacity, and pricing.

The strategy also established new employee processes with clearly defined roles and responsibilities, and helped leadership identify key performance indicators and measurement tools—which the transportation department still uses to drive discussion in weekly meetings.

Next, our team helped the manufacturer select and implement MercuryGate transportation management software. This tool optimized order consolidation and routing, mitigated risks associated with new opportunities, and tracked multi-leg shipments.

Returns You Can Measure

Thanks to West Monroe, the manufacturer decreased the size of its carrier portfolio by 20 percent, reduced its reliance on freight brokers, and reduced transportation service costs through better carrier selection and management. The food manufacturer also increased its freight capacity for peak season.

Overall, the changes led to a reduced transportation spend of over 10 percent, or $3 million, during the first year of implementation. The new processes and technology West Monroe implemented improved the company’s tracking abilities and enhanced its relationships with supply chain partners—all while maintaining top-tier customer experience.

Moving forward, the manufacturer is well-equipped to handle the evolving fresh food market.