July 2019 | Point of View

The productivity imperative: Gaining ground in economic booms and recessions

A recession is coming—soon. Three-quarters of CFOs and 59% of economists expect it by the end of 2020.

A recession is coming. Businesses can prosper by focusing on making productivity improvements before it arrives. We’re 11 years into a typical seven-year recession cycle, and three-quarters of CFOs expect a recession by the end of 2020. Increasing organizational productivity before the recession hits will be vital if businesses want to seize upon the opportunity to capture market share from weakened competitors. The imperative is amplified by the ongoing war for talent, which makes it critical to maximize productivity across your existing workforce in order to grow.

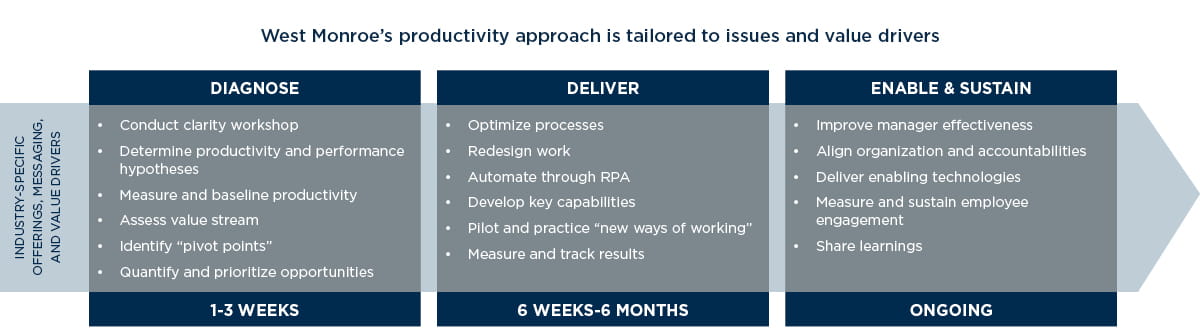

- The biggest productivity gains can be seized in four key categories. Business leaders would do well to concentrate on process optimization, process automation, work redesign, and competency development/ employee engagement if they want to drive productivity growth. Central, too, is ensuring that front-line management, who can make or break productivity within an organization, is as effective as possible.

- Executives need to balance their goals with realistic timelines to achieve actual results. It can be tempting to take on massive, multi-year undertakings that promise big gains and lofty returns for shareholders. But executives need to be pragmatic about how long it will take to get what they want. That’s why focus is a critical success factor. Be realistic. Set goals carefully. Make sure you understand how to get there. And don’t forget to measure what matters.

- Companies are smarter this time around. The last economic downturn left its mark. Due to its severity, many organizations jumped to dramatic cost- cutting out of necessity—despite the long-term effects some of those cuts would have on their businesses for years to come. Those organizations have learned from past mistakes and are now savvy enough to focus on “elevated” ways to reduce costs—using automation and analytics to drive productivity and efficiency that is sustainable over the long term.

The question on every business leader’s mind right now is: What choices can I make now to prepare for the inevitable?

The answer, we think, comes from recent history: During the last downturn in 2009, 20% of companies in the bottom quartile leapfrogged to the top 20% by recession’s end—and they did so by focusing on productivity gains before the downturn hit.

By contrast, the least successful were those who, in lieu of prior preparation, devolved into crisis mode and made cost reduction the top goal—which is why it’s troubling that 72% of executives we surveyed said reducing operating cost would be their principle area of focus if a recession hit tomorrow.

Chapter 1: Having learned from previous recessions, companies are approaching productivity differently

Time and time again, we’ve seen that going into recession crisis mode doesn’t work out for companies in the long term. Take Sony back in 2000 for example: During that downturn, the company cut its workforce by 11%, its R&D by 12%, and its capital expenditures by 23%. While these tactics may have increased its profit margins slightly in the short term, its growth in sales declined from an average of 11% in the three years leading up to the recession to 1% following it.

Even today, Sony has failed to regain momentum, trailing behind market leaders in developing new products like e-readers, gaming consoles, and hi-def TV sets.

Many organizations have learned from past downturns and are preparing differently. Ford, McKesson, Pepsi, and Procter & Gamble have announced high-efficiency mandates. HSBC and CVS are now investing heavily in digital modernization—including automation and data analytics— to drive long-term, sustainable efficiencies.

These companies know that increasing productivity isn’t just something you do before or during a downturn, but should be a priority in an up-economy as well, where knowing which levers to pull can help increase sales, widen margins, and generate growth that could not otherwise be possible.

The problem is, even if leaders agree that increasing productivity is crucial, many don’t know how to get started or face challenges in executing their plans. The good news is that even if you feel you’ve reached a productivity plateau, there’s still time to learn how to move past it and make progress again.

Chapter 2: You may know you need to prepare. But that doesn’t always mean you know how

Every business leader wants to increase productivity. But that doesn’t mean they know how to make it happen. Most are unsure where productivity opportunities exist, and when they do, they tend to take on too much too quickly, addressing the symptoms and not the root cause.

In our long history working with Fortune 100 companies to nimble, mid-market enterprises, we’ve never found a business that couldn’t improve their productivity. And in doing this work, we’ve identified that the biggest productivity gains typically come from one of the four following categories: process optimization, process automation, work redesign, and capability development.

Focus your attention in these areas, and you’ll emerge from the coming recession ahead of the pack.

Process optimization

Organizations create and deliver their products and services to customers through chains of connected processes. It follows, then, that improving any one process can drive a productivity benefit by either requiring fewer resources (e.g., materials, labor, etc.) to complete it, or by increasing the speed at which it can be performed (e.g., throughput, speed of service, etc.). The same holds true for organizations’ non- customer facing, back-office operations.

Yet improving some processes can generate significantly greater return on investment than others. For instance, according to a recent West Monroe survey with American Banker, 79% of banks report they’ve been extremely or very successful in improving productivity—yet only 34% have an efficiency ratio better than the industry standard (50%). It’s clear that they’re doing “stuff” to improve productivity—it just may not be the right stuff. Knowing which processes should be prioritized for improvement—and the order in which they should be improved—is the essence of process optimization.

When one of the largest water utilities in the nation came to us just before embarking on a multi-year implementation of meter-to-cash technology—one that would radically change its services and customer experience by automating meter-reading and speeding up the billing process—we put process optimization into practice.

This meant that before technology vendors were selected, we mapped all core business processes from start to finish to identify steps that brought little to no value, eliminate steps that would slow down the technology implementation, and seize on process changes that would engender quick wins. Some of these process changes helped the utility save over $1 million annually—with less than a week’s work of effort.

To optimize processes within your own organization, keep the following principles top-of-mind:

- Understand and align on desired outcomes and the KPIs needed to measure these outcomes. With the utility cited above, the initiative only worked because the organization understood its desired outcomes: namely, revenue recognition and improved monitoring/ maintenance of meter assets. With that outcome in mind, we could develop KPIs to measure success, such as billing times, customer claims complaints, and meter outages per quarter.

- Leverage proven process improvement methodologies to identify product/service value streams. A blend of surveys and direct observation, for instance, can often reveal the biggest drains on productivity: manual workarounds, excessive administrative time, systems that don’t talk to one another, lack of data to enable decision making, and more. Instead of figuring out how to do this on your own, turn to methodologies like lean, kaizen, or others to get to value faster.

- Prioritize improving the processes that offer the greatest ROI or desired results. Once an organization knows its desired outcomes, prioritize those areas where maximum impact could be made with least effort, along with what drives value. This often comes down to simply understanding your customers. For instance, if your customers are digitally savvy and tell you that’s how they want to receive communications, don’t invest in direct mail and call centers.

- Analyze those processes to identify opportunities that eliminate waste, reduce non-value-added activities, enhance quality, and increase volume. Our productivity assessment identifies 100+ opportunities for improvement. That’s why prioritization is key. We consider your goals—what is your time horizon for achieving productivity gains? How much change can your organization handle simultaneously? Is your top priority to drive top line revenue (focusing on customer- facing improvements) or operating efficiency (focusing on back office gains)?

- Mitigate complexity and variation to drive long-term efficiency. Short-sighted approaches to productivity can wreak havoc on an organization. For example, eliminating local HR representatives to reduce “overhead” without addressing who will take on the role previously held by HR leaders (hint: it’s your managers!) will eliminate any gains in cost efficiency—and then some. Thinking “big picture” ensures your productivity gains will be long-term sustainable.

Process automation

Automating manual processes—by, say, re-keying information and workflow sequencing—increases productivity not only by eliminating menial tasks, but by reducing wasted time, eliminating human error, and, most significantly in today’s war for talent, freeing existing employees to do more interesting and valuable work. This ability to retrain—or “upskill”—your workforce will help prepare your business for a future where technologies will take over basic tasks, giving rise to a 24% increase in the demand for “people” skills; after all, social and emotional skills can never be automated.

Process automation cuts across industries. A financial services company, for example, found that using robotic process automation in one department could free up as many as 75 full-time employees. A dental insurer increased its daily outputs by 350% after replacing a time-intensive credentialing process that included manual keystrokes, disparate resources, screenshots, and a decentralized document storage system with an automated process. And nearly 70% of manufacturers say their implementation of IoT in warehousing, shipping/logistics/transportation, packaging, and document management has significantly increased productivity and profitability.

In a recent West Monroe survey, nearly 60% of managers said they spent at least three hours a day on manual tasks like email, data collection, and data entry. Activities like these make up 51% of the U.S. economy, accounting for nearly $2.7 trillion in wages.

Work redesign

Poor organizational structure hampers communication, hinders strategic progress, dampens employee morale, damages customer experience, and, ultimately, reduces productivity. At the root of these problems in several industries tends to be rising customer expectations (i.e., a desire for choice, customization, and self-service) alongside outdated systems that slow down workflow and fragment crucial data. In a recent West Monroe survey with Workforce magazine, for instance, 43% of workers stated that they still have to re-key information into multiple systems.

To recapture lost productivity, business leaders must redistribute work to align with core capabilities and strategic initiatives. To that end, they should:

- Modernize organization design and reporting structures. One simple way to do this: reduce paper. It can cut down on mail influx and clutter, while enabling knowledge- sharing among employees via the cloud. It can also save money and deliver value to customers. A large health insurer we worked with, for instance, saw an average of $6 million in savings per 1% customer adoption of their self-service digital platform.

- Reduce rework through system consolidation. By consolidating 40 different business applications, a financial institution now saves 17,000 hours a year. Another found that automation could free up hundreds of full-time employees for more complex tasks. While, according to that West Monroe and Workforce magazine survey, over 70% of companies have introduced similar technology to increase employee capacity, there’s still plenty of room for improvement: only 12% have adopted automation, and only 18% have redesigned processes alongside these new technologies.

- Update work sequencing and identify critical path. A leading medical device manufacturer discovered their decade-old systems were delaying equipment implementation and impacting top-line revenue. After numerous interviews, process mapping sessions, and root-cause analysis sessions, our team identified 86 pain points within their current operations. We then focused on those initiatives that would increase productivity and growth potential, like removing a redundant statement- of-work process and streamlining the installation completion notification process. The result was a $3.3 million increase in annual revenue.

- Outsource or offshore non-core capabilities to a lower cost provider. The key here is to remember that although outsourcing can seem like a quick-cost solution, it’s crucial to identify the right processes to outsource in order to ensure a smooth transition and successful implementation.

Capability development

The war for talent requires that businesses keep every employee engaged, productive, and high-performing. Yet despite companies increasing spend to nearly a billion each year on solutions to this problem, employee engagement remains at record lows, costing businesses $600 billion in productivity losses, according to Gartner.

The reasons for this can be manifold, but one common mistake is thinking that simply providing employees with new digital tools and capabilities will induce higher levels of engagement. While those tools are undoubtedly important, it’s crucial that business leaders don’t forget about the human aspects: how, for instance, every employee craves a holistic journey within their company.

To that end, it’s important to not only identify blind spots in current employee skillsets, but also to lay out a comprehensive training plan to improve or create new competencies to fill those gaps. Upskilling your existing workforce in this way can maximize productivity, increase employee engagement, reduce turnover, and ultimately improve customer experience.

This happened recently at MultiCare Health System, where a department struggled with high turnover and low morale—an issue that regularly resulted in mishandling of appointment scheduling, customer service issues, and overall subpar patient experiences. To remedy the matter, West Monroe made recommendations based on insights from an employee engagement assessment, live observations, and MultiCare’s own annual survey. New strategic initiatives included updated training programs, revised job modifications and career paths, performance dashboards, and new incentives for employees, like the ability to work from home and a points-based rewards programs. The outcome? Improved patient and provider experiences, as well as 90% of the department now being actively engaged in their work.

What’s more, a re-orientation like this bears fruit in a downturn—particularly when it remains focused on maximizing value to the customer. During the 2000 recession, for instance, Office Depot cut 6% of its workforce while Staples increased its by 10%, primarily to support the high-end categories and services it introduced. The shift toward these offerings (e.g., personalized printing, business, and tech services) ultimately worked to serve their customers better and engage their employees. In the three years following that recession, Staples was, on average, 30% more profitable than Office Depot.

Chapter 3: Focusing on front-line management effectiveness is critical

Of the $600 billion in productivity losses due to unengaged employees, $410 billion stems from ineffective managers.

After all, they play a critical role in enabling employee engagement, as they’re tasked with driving C-level strategy down to day-to-day operations. From a cultural standpoint, they’re responsible for modeling positive examples for lower-level employees and instilling a mindset of productivity; organizationally, they must also delegate effectively, identify root causes of productivity leakages, ensure effective communication, and find ways to upskill their teams.

Yet a Gallup study found that 70% of managers don’t feel well-equipped for the job. Again, productivity growth seems to come down to time: how to free up these employees from the administrative work that takes up more than half their workday? And again, it comes down to automation and work redesign; if managers could delegate or automate menial tasks, they could spend their recouped time on running more productive operations, driving sales and loyalty, and improving customer and employee experience.

Getting there requires a comprehensive approach, using qualitative and quantitative methodologies. These methods helped a global coffee retailer improve the effectiveness of its district managers. An employee journey map depicted a week in the life of such a manager, delivered a breakdown of how and where their time was allocated, as well as a gap analysis and critical variables that, when addressed, increased their district managers’ effectiveness and overall productivity.

Chapter 4: To achieve these goals, executives must balance their priorities, timeline, and expectation

As we suggested earlier, achieving impactful productivity gains is easier said than done. Time and again, a huge disconnect appears between what executives want and how long they realistically have to achieve it.

Highly publicized efficiency mandates—like those announced recently by Ford, McKesson, Pepsi, and P&G— are multi-year strategies. They often focus on massive undertakings, such as introducing artificial intelligence or creating a digital business, that are aimed at yielding the lofty gains shareholders desire. But these are high-effort tasks, with long timelines.

If you don’t have that amount of time, you can still achieve meaningful gains. It’s not so hard to get started—we’ve gotten productivity initiatives up and running in just 60 days—but it does require a different approach. You might consider, for instance, a minimum viable product framework that can help businesses capitalize on speed-to-market, with initial cost savings that can then be optimized over time. This would be a particularly attractive option for more nimble, middle-market organizations.

Whatever your specific business case, focus is a critical success factor when it comes to increasing productivity— be it during an economic recession or boom. Trying to do too much too fast can quickly ruin the viability of all your initiatives. So be realistic. Set your goals carefully, then make sure you understand how to get there. And be sure to measure what matters.

Maybe this will mean developing your own productivity “criteria,” which leaders can get started on by asking questions like: What can I accomplish in six months? In 12? Can I do this all at once, in separate workstreams? Am I prioritizing projects with the highest potential ROI and/or the lowest cost?

Because, when it comes down to it, true productivity is easier said than done. Especially today, when employees are burnt out, the talent pool has run dry, and there’s a nagging feeling of: We’ve hit a plateau, and we’ve got to do something differently to move forward.

We know the feeling—we’ve seen it time and time again, in nearly every industry, with companies small and large. Yet we also know what it’s like to feel not just busy, but productive; to be optimized by new digital technologies rather than burdened by them; and to do more with what you already have, in good economies and bad.

After all, that’s the potential of productivity. At West Monroe, we’re here to help make it a reality.