April 2020 | Resource

Checklist: Key steps for manufacturers to get ‘back to business’

Outlining the short- and long-term considerations for both essential and non-essential manufacturers

Checklist: Key steps for manufacturers to get ‘back to business’

Manufacturers are at the forefront of the unprecedented, drastic change in global economics caused by the COVID-19 pandemic.

Primarily driven by the issue of workforce and community health and safety, the pandemic will cause lasting impacts across business operations, human behavior, supply chains, and governmental policy. To stay ahead of competitors during this time of uncertainty, manufacturers must rethink their short-term, medium-term and long-term plans to address their new reality. We believe this is determined based on the essential or non-essential products sold and the manufacturer’s level of digital maturity. When looking specifically at manufacturers, it’s clear that COVID-19 has disrupted global supply chains and created an uncertain future for many manufacturers.

- Around 80% of companies expect a supply chain impact from COVID-19 disruptions

- 40% of employees are projected to be unable to work

- 44% of manufacturers sourcing from China did not have a risk mitigation plan in place(2)

- 64% of B2B businesses have less than 20% of sales through e-commerce

- Only 14% of retail sales occurred online in 2019

With uncertainty, volatility, complexity, and ambiguity still surrounding the COVID-19 situation, how can manufacturers respond?

The Key Issues

Let’s first dive into the macro issues the coronavirus has created for manufacturers.

The core issue and priority at hand — global and community health and safety — is creating broader impacts on the manufacturing world. The priority of decreasing the spread of COVID-19 has resulted in stay-at-home orders and social distancing guidelines, which changes how we do business today. This will leave a lasting impact for years to come as consumers and businesses continue to evolve operations post-coronavirus.

Today: Disrupted business operations -->Tomorrow: Evolved Business Operations

- Virtual/remote workforce will become a normal work environment

- Advanced (I4.0) manufacturing is expected to enable increased insights and flexible manufacturing

- Virtual operations will become a normal work environment

- New revenue channels will be created as a result of new demand opportunities

- Product-as-a-Service (PaaS), or customer-centric versus product-centric models will drive market leadership

- Sector consolidation (M&A) of non-essential businesses will change the marketplace

Today: Disrupted Human Behaviors--> Tomorrow: Evolved Human Behaviors

- Digital buying is expected by customers

- Digital self-service is expected by customers

- Workplace/office personal protection equipment (PPE) will increase to include preventative and predictive measures

- Do-it-myself (DIY) is expected by customers

Today: Destabilized Governmental and Economic Policy --> Tomorrow: New Governmental and Economic Policy

- Preparation for inflation is necessary for a post-economic downturn

- Commodity volatility will continue to disrupt supply and pricing

- Protectionist economic policy will emerge and significantly alter business operations

Today: Disrupted Global Supply Chains--> Tomorrow: Evolved Global Supply Chains

- Nearshore/onshore manufacturing will de-risk supply chains and replace offshoring

- Shortened and regionalized supply chains will be implemented to avoid trade wars

- Digitally threaded supply chains will become the new normal

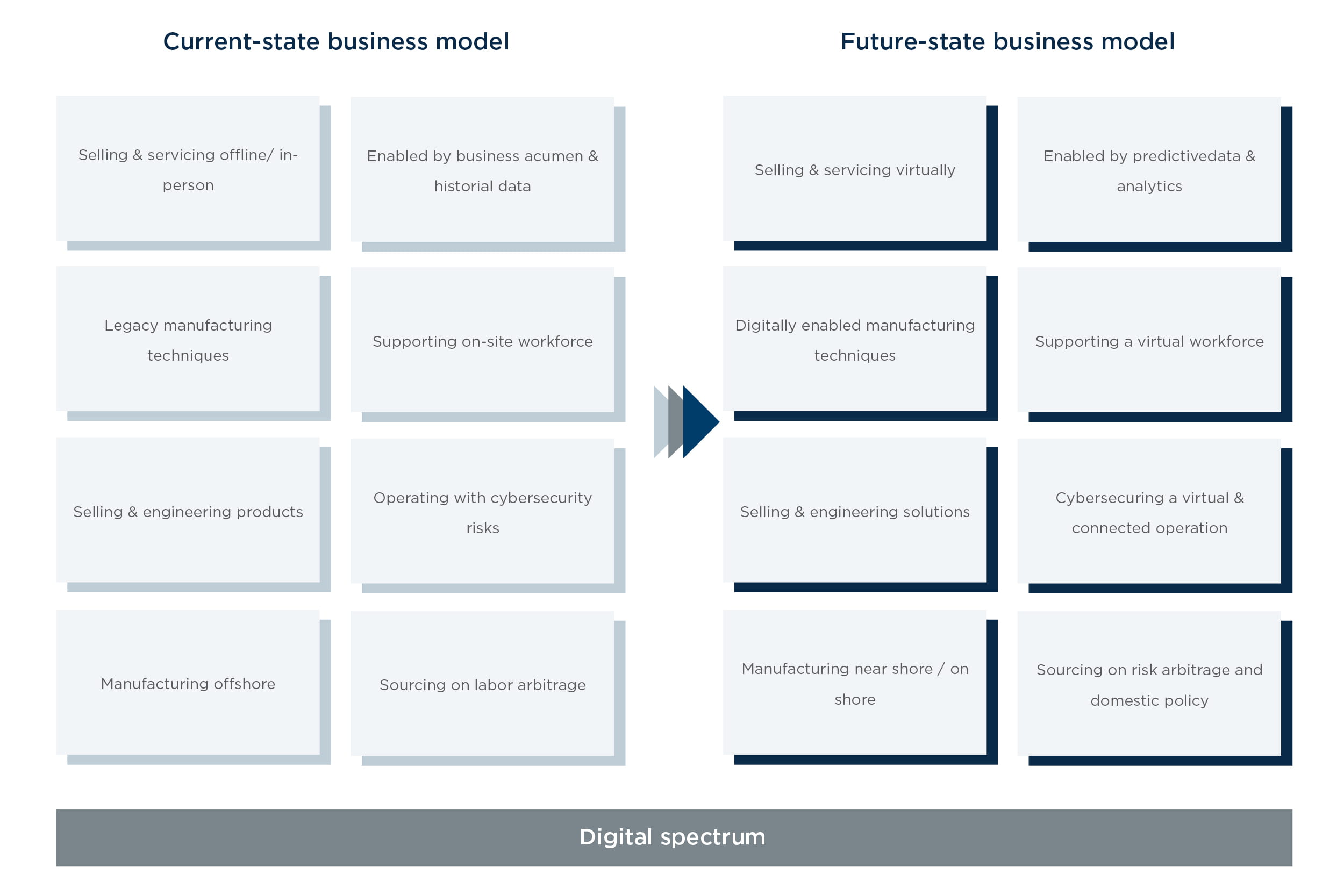

The Future State

We believe manufacturers must capitalize on the moment to create sustainable advantage or they will become obsolete. While the concept of a digitally-enabled business is not new in manufacturing--which has seen strong strides in Industry 4.0 capabilities over the last few years--the concept of shifting toward one is becoming an immediate, rapid, and unanticipated expectation with the reduction of human interaction across suppliers, customers, operations, and employees.

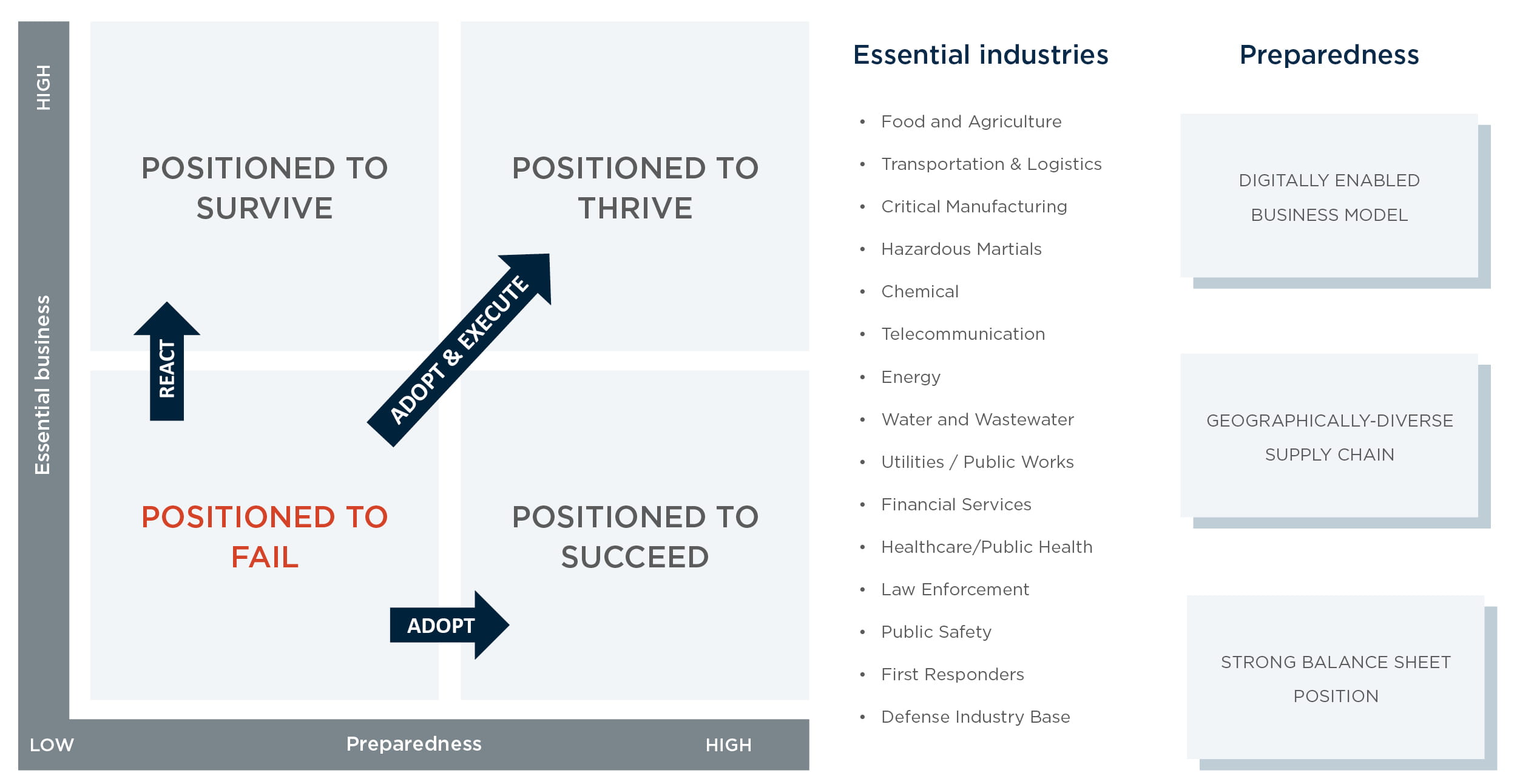

Resetting for Success

Broadly, each business’s response to COVID-19 will vary based on each business and its level of preparedness. Preparedness is defined by the presence of digitally-enabled business models, geographically diverse supply chains, and strong balance sheet positions. Those best positioned to thrive are essential and highly prepared manufacturers with the capabilities in place to accelerate their teams to immediate execution. Companies that are non-essential but highly prepared are positioned to succeed during this time because they are still digitally connected with their customers and can enable a remote workforce. Companies that are non-essential and unprepared are positioned to fail during this time because they do not have the means to operate with the shutdown occurring. However, there are ways for companies that are non-essential and not prepared to quickly pivot their business strategy to position themselves to survive. A response plan should be developed, regardless of position.

Building a Response Plan

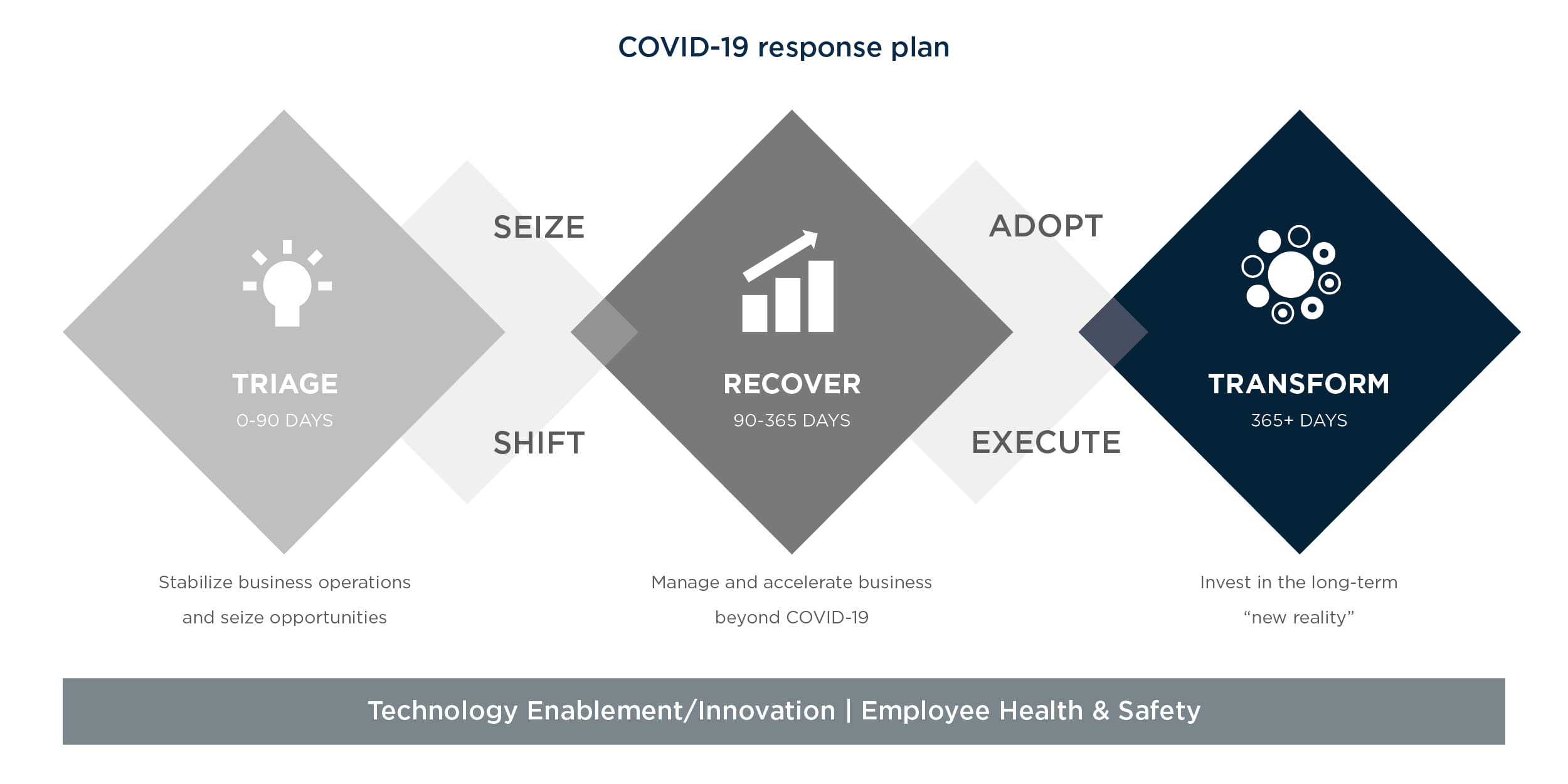

Building a plan of action can be difficult, especially in times of uncertainty where each day feels like a week and businesses are still overcoming the initial shock of COVID-19 to daily operations. Right now, manufacturers should focus on triaging their businesses over the next 60 to 90 days to not only stabilize their business but also to inform their long-term strategies or they risk falling behind competitors. From there, they can move into recovery and transformation phases.

There are 3 key focus areas for essential and non-essential manufacturers to set up their long-term response plan for success.

Essential Business Triage Checklist

STABILIZE BUSINESS OPERATIONS

Manufacturers must first assess current operations and supply chain to respond to demand shifts.

- Respond to demand shifts - understand inventory and operations position

- Assess current suppliers - secure interim supply and logistics sources

- Increase plant capacity and productivity

CUSTOMER SEGMENTATION & ENGAGEMENT PLAN

With an increase in demand, manufacturers should ensure they are equipped to service customers effectively and be able to prioritize strategic customers.

- Identify critical customers

- Enable digital selling capabilities

- Adopt order fulfillment/customer service capability

SAFEGUARD EMPLOYEES

Manufacturers should prioritize safeguarding their employees on the shop floor and establishing strong IT capabilities to manage virtual workforce when possible to maintain continuity in operations.

- Enable remote workforce

- Identify and implement operational health and safety measures (PPE, safe distancing, digital collaboration)

- Create cyber secure work environments

Non-Essential Business Triage Checklist

PRESERVE CASH

Non-essential manufacturers must focus on responding to the downturn in business through cost-cutting and analysis of current business position to determine if they should stay, sell, or liquidate as a result of the unanticipated downturn.

- Identify new demand scenarios

- Manage on-hand and in-transit inventory and decrease working capital

- Adjust production projections

- Conduct liquidate vs. hold vs. sell analysis

- Right-size workforce

SEIZE MARKET OPPORTUNITIES

To stay afloat, non-essential manufacturers must evaluate opportunities in the marketplace to pivot their existing products and customers to more favorable outlooks.

- Define demand profile by segment - customer, channel, product

- Ready to seize market conditions (M&A, market share expansion, etc.)

- Reset cost to serve

- Enable digital selling channels

SAFEGUARD EMPLOYEES

Like essential manufacturers, non-essential manufacturers should prioritize safeguarding their employees on the shop floor and establishing strong IT capabilities to manage a virtual workforce when possible, to maintain continuity in operations.

- Create an employee retention plan

- Enable remote workforce and prepare for shutdowns

- Identify and implement operational health and safety measures (PPE, social distancing and collaboration protocols)

- Create cyber secure work environments

Depending on the situation, each business area may need to take the following actions to enable the response plan:

Strategy

- Evaluate hold vs. sell vs. liquidate position

- Evaluate M&A opportunities

- Evaluate market share opportunities

Marketing and Sales

- Enhance eCommerce and customer channels

- Identify new customer acquisition opportunities

- Redefine the customer experience

- Enable a new forecasting discipline

- Identify customer retention strategies

- Ensure adequate customer support

R&D

- Complete a product portfolio analysis

- Evaluate new product development opportunities

- Understand demand sensing

Technology

- Enable virtual workforce collaboration tools

- Enhance cybersecurity

- Increase infrastructure support for customer support teams and virtual workforce

Health & Safety

- Ensure governmental policies are followed

- Enable predicative and preventative measures to ensure employee health & safety

Operations

- Assess and create demand response

- Assess and create revised S&OP

- Strengthen supplier network

- Enable plant capacity and productivity to meet revised demand

By acting now, companies can stay ahead of competitors and get back to business.