Showcasing Manufacturing 4.0 Technology for the Next Generation

Manufacturing needs to tell a new story about M4.0 technology as an exciting and rewarding job-enhancer to attract the next generation of employees

This article was originally featured in the Manufacturing Leadership Journal in August 2020. ©2020 Manufacturing Leadership Council, a division of the National Association of Manufacturers. All Rights Reserved.

Imagine a college graduate who has recently finished near the top of her class and is now fielding job offers from various industry players – healthcare companies, financial institutions, and large multinational retailers. So, why isn’t she interested in manufacturing too?

Can you blame her for not pursuing a manufacturing career? Growing up, after all, she has heard about the impact of the Great Recession, the crash of the auto industry, and increasing globalization. What she has seen about manufacturing in the news tends to be dark and dingy factories, usually in rural areas away from the hubbub of a metropolitan city, many shuttering their doors, and jobs moving overseas or being replaced by automation. Her parents may not be encouraging either. In a 2017 NAM report only three in 10 parents said they “would consider guiding their child toward a career in the field.”

It’s a familiar story for manufacturers. Data from the May 2020 U.S. Bureau of Labor Statistics suggests around 315,000 manufacturing jobs remain unfilled in the United States due to a lack of new available talent and the retirement of baby boomers. In a recent West Monroe survey, The Future of Manufacturing in Minnesota, 60% of young Minnesotans also said they didn’t believe the manufacturing industry could offer a long-term career. Only 30% think its wages are competitive, and just 25% said manufacturing leverages cutting-edge technology. Many solutions to this problem have already been adopted. Educating kids about manufacturing at a young age. Partnering with vocational training and high schools to provide more apprentice and internship opportunities. Sponsoring AI and robotics labs in schools. Rotational management development programs such as those at GE or Honeywell. Adopting a German-style apprenticeship model in which students spend much of their time gaining hands-on experience.

These approaches are certainly vital. But more can be done, especially when it comes to reframing the story around technology in manufacturing and transforming what is often perceived as a deterrent (replacing workers) into a value-add. Doing so requires more than educational and awareness initiatives to get applicants in the door. It requires considered strategies for making and showcasing technology investments, integrating technology into a firm’s operations and culture, and articulating the true value of such technology to existing and future employees, particularly as we enter a post-COVID-19 world.

Correcting Misperceptions

First and foremost, it’s essential that the industry corrects the long-held misperceptions about manufacturing, misperceptions that, due to many economic forces, perhaps hold less true today than ever. That demands a new kind of industry pitch to that top college grad where manufacturers can tell an exciting new story about technology in manufacturing that helps to boost STEM education and public awareness and helps turn technology into a selling point for manufacturers seeking next generation leadership. That new story certainly has a lot to say.

1. Technology makes manufacturing work more exciting, transforming employees from task executors to analyzers

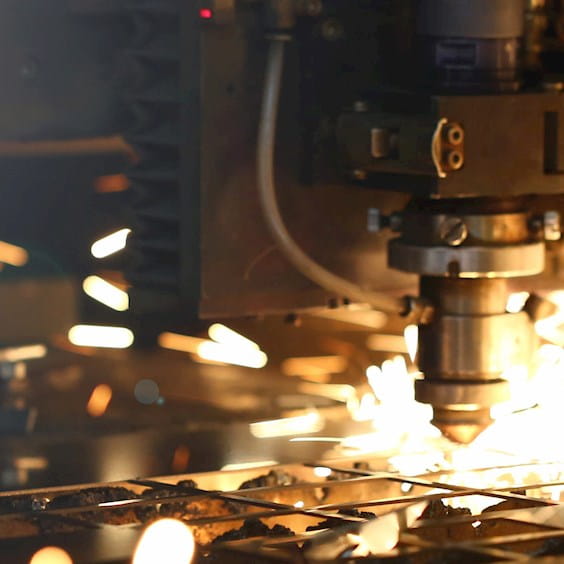

When many picture manufacturing jobs, they think of menial tasks repeated again and again. But with new technologies such as predictive analytics, IoT, or enterprise resource planning systems, employees become analyzers rather than mere task executors. Instead of repeating a task 1,000 times per day, an employee interprets those tasks for signals and exceptions to manage desired outcomes.

For instance, a maintenance mechanic’s job might be to replace a bearing on a pump, and that mechanic might have to do so every other week because it keeps failing. But with the right data on that machine, the mechanic can spot eccentricities (e.g., in a shaft piping to the bearing) that, if amended, will let the machine function for six months rather than a week. In doing so, the employee gains more autonomy over his or her work, becoming a manager rather than a maintenance mechanic. This is quite a different picture than the one painted by traditional representations of manufacturing roles.

2. Technology isn’t replacing jobs. It’s helping manufacturing companies thrive in the digital age.

Another prevailing misconception is that technology is replacing the work done by traditional factory workers. While this is certainly true in some instances, more often than not the organizations shuttering their doors are those who haven’t embraced technology enough.

In a recent survey by the National Center for the Middle Market (NCMM), middle-market manufacturers with annual growth rates of more than 10% assigned more importance to every facet of technology about which they were asked. 45% also said their employment levels would stay the same, while 28% said technology would actually grow the number of available jobs.

One reason for this is that technology drives up productivity, allowing manufacturers to do more with the same workforce. For example, by using prescriptive analytics to drive production planning, one middle-market manufacturer saved $200,000 per week. These productivity gains become especially important now, in the face of a potential post-COVID recession. When asked last year about what they’d do first if a recession hit, 70% of executives said they’d refocus on operational efficiency. That’s where new technologies can really help.

The productivity imperative: Gaining ground in economic booms and recessions

Read More3. Manufacturing is coming back to the U.S. and technology plays a key role

Millennials and Gen-Zers now choosing career paths grew up just as supply chains were becoming hyper-globalized, a trend driven by, as Richard Baldwin, President of the Center for Economic Policy Research notes, the twin forces of Western knowhow and Asian manufacturing muscle.

Yet in the past few years, a confluence of divergent forces is attempting to bring back American manufacturing and re-regionalize those supply chains. Wages in China and other offshore destinations have gone up along with transportation costs. Several U.S. companies have pivoted to more regional suppliers amid recent tariff wars. And consumer expectations have peaked, with many now demanding delivery times that match Amazon Prime’s 48-hour standard. As the dust settles around COVID-19, we should expect these supply chains to contract even further.

Technology plays a fundamental role in this trend, too. 3D printing, which nearly half of supply chain managers plan to implement in the next few years, can rapidly create parts once procured abroad. In-depth visibility into these newly regionalized supply chains will help as well, allowing organizations to better anticipate demand and deliver customized products.

This reshoring trend, enabled in part by technology, should be appealing to a new generation of talent that is increasingly looking for purpose in their work and which believes that manufacturing is important to America’s future. For instance, despite some antipathy about working in manufacturing, 97% of young Minnesotans say the industry is important to the future of the state.

Smart Technology Investments

While educational and awareness endeavors are crucial to attracting next generation leadership, manufacturing leaders must also ensure that technology is smoothly integrated into employees’ experiences to improve engagement and retention once they’re on the floor.

For instance, drastic changes all at once might provide a shock that weakens organizational culture and may displace significant investment. Any technology strategy should therefore start by assessing what an organization already has, what its pain points are and what its overarching digital vision is, and then progress with small, incremental changes with requisite change-management processes in place each step of the way.

The following strategies for investing and integrating technology investment flow from this philosophy:

1. Consider a build, borrow, and buy methodology for technology investment

The need for a higher-skilled manufacturing workforce can drive executives’ decisions regarding how best to adapt their organizations’ culture. In other words, how do you position technology investments such that they add more value than they cost in budget and resources, don’t overwhelm existing employees, and attract next generation talent?

One methodology that might be useful, especially after an organization has assessed its current skills gaps, opportunities, pain points, and overall digital vision, is to think of investments in terms of what manufacturers can build, borrow, and buy. Manufacturers should consider building internal capabilities to drive innovation and a fail fast culture. This might entail creating an internal innovation hub for rapid prototyping new capabilities. Building these internal processes will be particularly important as we enter a new stage of market volatility and supply chain uncertainty in a post-COVID world.

At the same time, manufacturers may think about borrowing talent through consultancies, if, say, they need to integrate a new technology initiative rapidly, on a timeline of 3-4 months.

Buying, meanwhile, may be useful for firms looking to take their organization to the next level via strategic acquisitions that can accelerate the development of a certain skill set or capability instead of creating it from scratch.

Throughout this process, executives should remember they’ve already won half the battle. Most have already made significant investments in technology and software. These operational technology systems are constantly generating data that is waiting to be leveraged. Thus, value creation may not require huge investments in new technology, but simply analyzing the available data using the technology already at hand.

2. To integrate technology successfully, collaboration and value articulation are key

When it comes to integrating new technology into a manufacturing organization, successful implementation begins with a clear articulation of the tool’s value, allowing employees to answer the question: “Why will this make my job better and easier?”

This articulation helps reframe manufacturing perception by emphasizing technology’s role in fueling, not hindering, long-term manufacturing careers; how technology empowers employees to do more autonomous, sophisticated, analytical work; and how technology creates new, safe, and innovative career paths in the industry.

Predictive analytics tools, for example, provide value to maintenance operators by allowing them to predict with a high degree of certainty when a specific part might fail. Instead of waiting for it to break and reacting when the problem occurs, operators can work proactively and plan ahead of time to prevent any issues from happening. This greatly reduces the stress involved in such operators’ jobs.

Sharing the Vision

When implementing new technologies, executives should also keep their overall pain points and vision top of mind. You can’t articulate the value of a new technology if you aren’t using it to address a specific issue or seize a particular opportunity. Defining and sharing this overall vision can inspire an aspirational culture and help align employees with the mission of their employer and the industry at large.

If a third party gets involved, they need to work alongside employees who will actually use the tool, from value and strategy planning, through execution. Working in tandem throughout the lifecycle of the project ensures that when the third party leaves, the knowledge and capabilities don’t leave with them.

Adequate training processes, including training materials, cross-training, or mentorship programs within the organization, also play a vital role. Organizations should be sure to develop these programs and/or materials to make sure the total value of each new tool is explained and retained.

A third party that works with, or alongside an internal team, is never a replacement for good change management. There are new technologies that allow these rollouts to scale more effectively across facilities like video and online interactive training courses. There are even cases for augmented reality (AR) to help employees adjust to new tech-enabled processes related to safety, for example, that might be deployed.

Redefining the Future

By retelling the story of technology in manufacturing, a college graduate assessing her career path will no longer see manufacturing as a failing, antiquated industry. Instead, she will see a vibrant, modern industry where technology is creating new opportunities for sophisticated long-term careers. She will see how technology is helping bring the industry back to American soil, and where she has the potential to be part of an exciting, innovative transformation.

She might also recognize how those new digital tools have already changed some manufacturers’ fundamental business models. Rather than merely producing products, many have already shifted to producing products-as-a-service (PaaS) offerings. The auto industry is a prime example of how this trend has come to the fore. Nissan, for example, is piloting a vehicle subscription service to provide greater choice and flexibility to customers with no long-term contractual commitments, while Rolls-Royce is leveraging data from IoT sensors to optimize the customer experience and their own operations.

This is just one aspect of the new reality of manufacturing 4.0. To attract and retain new talent, the industry must do a better job of articulating how it is also ushering in change in ways that improve the entire employee experience. That’s the winning combination for manufacturers to adopt to ensure they have the forward-looking skills they need to solve new problems arising from contracting supply chains and help the industry emerge from unprecedented economic disruption.

For manufacturing, redefining outdated perceptions and telling a new and exciting story about the industry is critical to its long-term success. After all, it’s the coming generation of talent that will take manufacturing into the future.